rockwell hardness test weights|mohs scale of hardness chart : agent The Rockwell hardness test is widely used to standardize the hardness of metals. Do you know the Rockwell Hardness Test procedure? Read on to learn more about how to perform a Rockwell Hardness Test. . Apply the minor load: A minor load of predetermined size and weight is applied to the test sample using a diamond or an indenter ball. In the .

A determinação e força dessa mulher idosa são inspiradoras e merecem nosso reconhecimento. Neste artigo, vamos explorar mais sobre a história da idosa da carreta .

{plog:ftitle_list}

22 horas atrás · Spotify is rolling out a new feature called Song Psychic that will allow its customers to ask Spotify questions and get answers in the form of music. The addition .

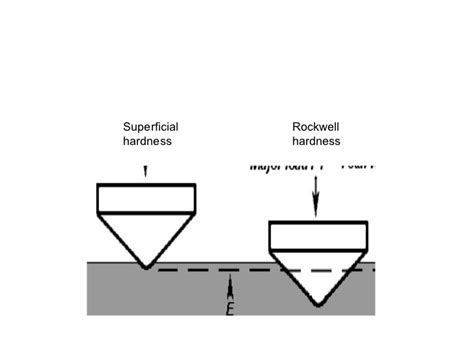

Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell . The Rockwell scale is a hardness scale based on indentation .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .

The Rockwell hardness test is widely used to standardize the hardness of metals. Do you know the Rockwell Hardness Test procedure? Read on to learn more about how to perform a Rockwell Hardness Test. . Apply the minor load: A minor load of predetermined size and weight is applied to the test sample using a diamond or an indenter ball. In the .These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table The machine provides a continuous direct readout for both the weight and the percentage moisture loss through the entire cycle. It has a build-in timer. . The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. The other tests .

Get more done with the Wilson RH2150 Rockwell Hardness Tester. Through its vast capability of testing scales and large load range from 1 to 187.5 kgf, the RH2150 caters to diverse applications.

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to inspection labs.Wilson Rockwell JS & OUS Series Superficial Hardness Tester Weight Set 0.00 Wilson Rockwell TT Twin Tester Series Weight Set ,240.00 Wilson Rockwell Tukon Microhardness Parts

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20-70). . Test procedure consists of a preload of the specimen using the force of the elevation screw and a test load using the weights and lever arm assembly. Be .The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a . * Weight 75/50g 80g 75g 250g Max. hardness of sample940HV 940HV 1000HV 650HB Preparation of surfaceThe Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

Phase II Hardness Testers accurately measure hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120° diamond indentor in the C-scale (HRC 20-70). Soft materials are tested using a . Open the test kit and remove the 3 weights. Clan and oil/grease from these weights.

rockwell hardness testing chart

rockwell hardness tester diagram

Rockwell hardness test according to the material hardness, thickness of the test, can choose A different head and test, and the different scale, says the most common have A, B, C scale, in the . Total test force by the main test force (produced by the weight of the weight) plus early test force, (7) the buffer rack shaft (8) on the plunger (9 .

Rockwell hardness testing machine series Versatile smart models 3 models to suit practically every application Features Specifications External dimensions (512) 434 65 218 . Total test force setting Weight change Dial switching Total test force control Motor drive Button start Motor drive Automatic start Test force duration 3-5.5 s setting Manual

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. . 6.7″ and depth of 5.3.” A storage case with accessories is included and the weight of the unit is approximately 150 lbs. This .

The selection of test force is automatically adjusted once you select your hardness scale. There are three test forces of 60kgf(588.4N), 100kgf(980.7N) and 150kgf(1471N) for Rockwell hardness measurement, and also three test forces of 15kgf(147.1N), 30kgf(294.2N) and 45kgf(441.3N) for Rockwell superficial hardness measurement.

ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . optional accessories: a Brinell indenter, a weight set and a measurement microscope. • Economy type tester loaded with the features of a more expensive tester such as anDefinition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major loadEach different Rockwell scale uses a different and load weight to test the material. The results of the test are given a code that includes HR and then the scale letter, i.e. HRA or HRB. . or aluminum that have been specially heat treated and calibrated for consistency. By using a test block, Rockwell hardness testers can be calibrated for .ROCKWELL HARDNESS TEST 1. AIM: To determine the Rockwell Hardness of a given test specimen II. APPARATUS: Rockwell Hardness testing machine, Test specimen. III. THEORY: . WEIGHT 7. BOTTOM WEIGHT 8. COVER 9. FRAME 10. OPERATING LEVER 11. SPINDLE SPRING 12. SPINDLE SHAFT 13. MAIN NKIFE EDGE 14. PIVOT VEE 15. PIVOT KNIFE .

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .A wide variety of load weights of 100, 50, 30, 20, 15, 10, . The Rockwell hardness test uses a spherical steel indenter; hardness is determined from the penetration depth. For Rockwell hardness, there are two conditions that are used for polymers. The shore hardness test uses pin-shaped indenters, whereas a Barcol indenter is used in Barcol .

Rockwell readings are broken down into scales that are each designated by a letter that signifies the minor load, major load and type of indenter or penetrator required for the test. Most hardness testers have a chart on them that shows the various scales that the tester can test in or you can refer to a Rockwell Hardness Scale Chart.We offer Rockwell-Type Hardness Testers for every budget, including a full collection of accessories and hardness standards. . Built-in dial-a-weight system; Heavy-duty cast housing protects from dust and corrosion; Conforms to tolerances per ASTM & ISO 17025 Standards . . Portable Rockwell Testers; Hardness Standard Test Blocks; Service;

rockwell hardness test theory

rockwell hardness test pdf

WEBWatch and download Free OnlyFans Exclusive Leaked videos of Kenzie Reeves aka itskenziereeves in high quality.

rockwell hardness test weights|mohs scale of hardness chart